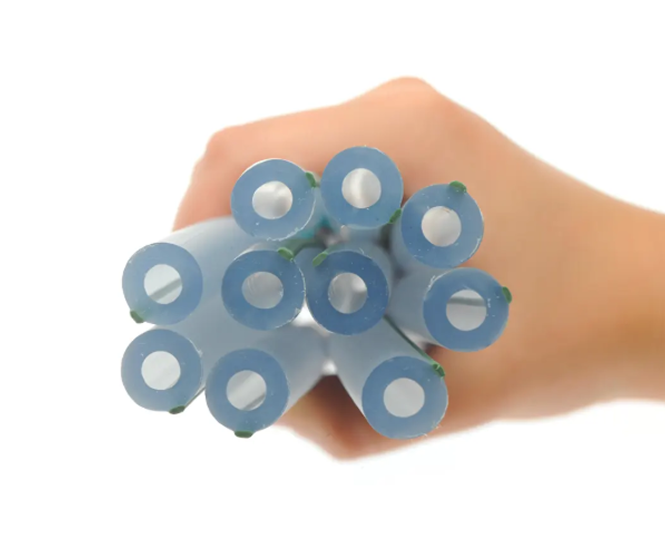

Premium Dairy Tubing for Pulsation and Air Systems

Lauren AgriSystems’ air tubing for milking systems are designed to optimize your dairy’s performance.

Options for short air tubes, twin tubes, and solutions for robotic milking systems (AMS), our tubing delivers consistent vacuum, superior durability, and exceptional flexibility for any dairy environment.

Explore our wide range of milking air tubing for dairy pulsation and vacuum systems.

Key Features of Lauren Dairy Tubing

Resistant to chemicals, biological materials, and extreme temperatures.

Maintains pliability in both hot and cold conditions for reliable performance.

BPA- and phthalate-free, ensuring safe use in milking systems.

Available in standard and custom lengths to fit your specific equipment needs.

Every tube is manufactured with full material traceability for quality assurance.

Milking Air Tubing Options for Your Dairy

Lauren AgriSystems milking air tubing is specifically designed for pulsation and air systems. Our short air and twin air tubes are compatible with a wide range of dairy equipment for seamless integration and reliable operation.

Short Air Tube

Made from high-grade polymer, this durable, flexible tubing is built for reliable performance in pulsation systems. Available in multiple inner diameters and lengths to match your setup, it ensures stable vacuum pressure and consistent milking performance.

Twin Air Tube

Engineered to support optimal pulsation in dairy milking systems, our Twin Air tubes are crafted from high-quality PVC and durable polymers for exceptional flexibility, durability, and resistance to extreme temperatures. Their rugged construction resists collapse, distortion, and hardening, ensuring consistent pulsation, reduced equipment wear, and improved milk yield in traditional parlors.

Twin Air Tube for AMS Robots

This AMS twin-tube silicone hose is designed for Lely A4 and A5 robots and provides enhanced vacuum stability and milk flow. The durable, dual-tube construction is ideal for high-use robotic milking environments.

The Relationship Between Twin Tube Length and Diameter

Studies conducted by Lauren AgriSystems demonstrate that longer tubing results in extended A- and C-phases, while shorter tubing optimizes B- and D-phases.

-

9/32” Tube:

Shorter tubing improves efficiency in high-yield parlors.

-

3/8” Tube:

Ideal for setups requiring greater airflow with minimal vacuum loss.